Feeder

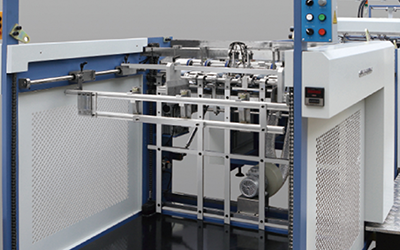

Sheets pre-stacker provides a continuous feed without a stop

Servo-controlled feeder head replenishes sheets

Sheets gap sensor for self-protection

The overlap regulator adjusts the sheets overlapped length

Side-lay regulator aligns sheets

Laminator

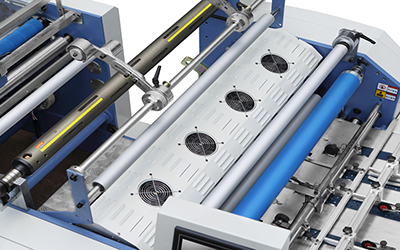

Electromagnetic-heated, chrome laminating roller

Hydraulic pump along with rubber roller exerts big, even and constant laminating pressure

Film mounted on a quick-change, micro-adjustable, electric air-shaft

Air-shaft ensures precise film release tension and speed

Film roll slitting and perforating mechanisms

Sheeter

Adjustable pro-active, anti-curl bar takes the curl out of laminated sheets

Steer wheels exert negative force on one side to help with sheeting

Stable and efficient pneumatic sheeting system with a rotatry knife

Stacker

Corrugated delivery system flattens and delivers sheetsSide joggers and back-stop stack sheets in order

Non-stop automatic stacker with a sheets counter

Others

Feed, overlap adjustment, laminating, sheeting and stacking are finished in one passTouch screen and control panel with colourful buttons

Optional

Secondary lamination unit improves laminated film fastness

Embossing system improves sheets exquisiteness to maximize the products value

UV film reinforcement system avoids film peeling and blisters

Chain knife sheeting system facilitates PET and PVC film sheeting

Advanced hot-knife sheeting system, combining hot-knife and the pneumatic sheeting system, features accurate and stable sheeting, no excess film, and high running speed

Code printing system that features a high-precision sprayer and precise printing is suitable for QR code printing

Plastic removal assembly contributes to plastic film recycling and reusing

|

Feeder

|

Mechanical side-lay regulator

|

|

|

Overlap regulator

|

Electromagnetic-heated laminating unit

|

|

|

Rotary knife

|

Pneumatic sheeter

|

|

|

High Speed Stacker

|

|

|

|

Optional

|

||

|

Embossing system improves sheets exquisiteness to maximize the products value

|

Secondary lamination unit improves laminated film fastness

|

|

|

UV film reinforcement system avoids film peeling and blisters

|

Chain knife sheeting system

|

|

|

Advanced hot-knife sheeting system

|

Code printing system

|

|

|

Plastic removal assembly

|

|

|

|

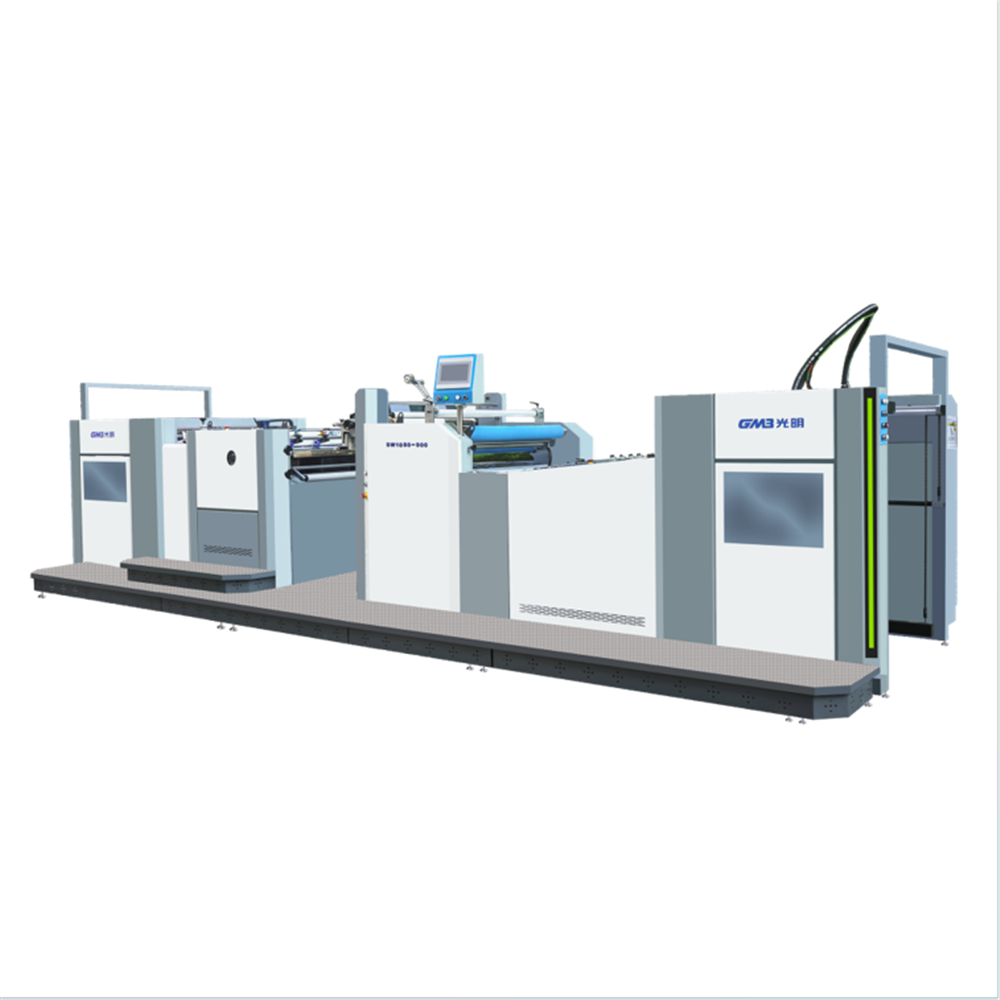

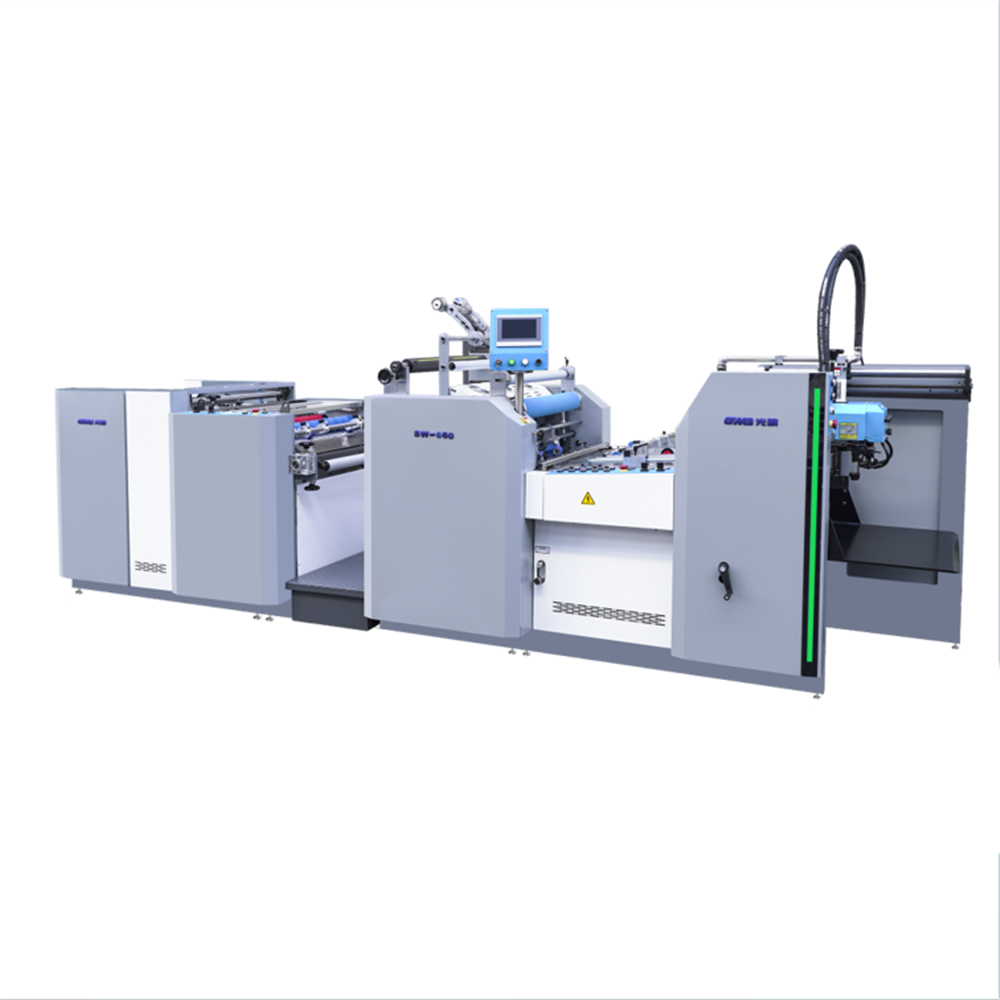

Model |

SW-1080*900 |

SW-1080*1300 |

SW-1080*1450 |

|

Max paper size (mm) |

1080x900 |

1080x1300 |

1080x1450 |

|

Min paper size (mm) |

300x260 |

300x300 |

390x450 |

|

Speed (m/min) |

0-100 |

0-100 |

0-100 |

|

Speed of chain knife (m/min) |

0-80 |

0-80 |

0-80 |

|

Sheet thickness (gsm) |

100-500 |

100-500 |

100-500 |

|

Total power (Kw) |

45 |

45 |

45 |

|

Weight (kg) |

6400kg |

6700kg |

6800kg |

|

Dimension (mm) |

7220x2500x1900 |

8000x2500x1900 |

8500x2500x1900 |

|

Pre-stacker length (mm) |

1660 |

1920 |

1920 |