Feeder

Sheets pre-stacker provides a continuous feed without a stop

Servo-controlled feeder head (oil-free vacuum pump) replenishes sheets

Sheets gap sensor for self-protection

The overlap regulator adjusts the sheets overlapped length

Side-lay regulator aligns sheets

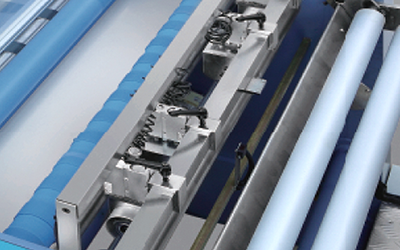

Slotting device

Double-sided slotting device

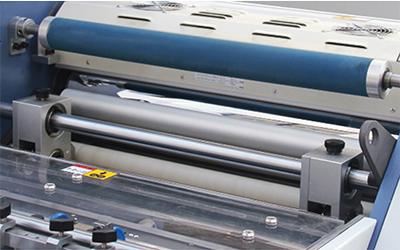

Laminator

Electromagnetic-heated, chrome laminating rollers and hydraulic pressure system

Double-sided laminating system

Film mounted on quick-change inflatable air-shafts

Air-shafts ensure precise film release tension and speed

Film roll slitting and perforating mechanisms

Embosser

Electromagnetic-heated, embossing rollers and hydraulic pressure system

Double-sided embossing system

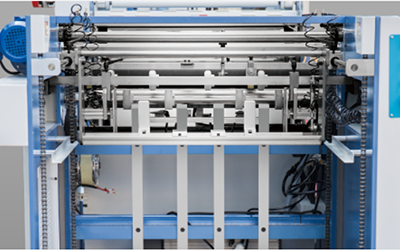

Sheeter

Adjustable pro-active, anti-curl bar takes the curl out of laminated sheets

Steer wheels exert negative force on one side to help with sheeting

Stable and efficient pneumatic sheeting system

Stacker

Automatic stacker

Others

Touch screen and control panel with colourful buttons

Double slotting & double-sided laminating and embossing are finished in one pass

|

Feeder head

|

Overlap regulator

|

||

|

Mechanical side-lay regulator

|

Double-sided slotting device

|

||

|

Double-sided laminating system

|

Double-sided embosser

|

||

|

Pneumatic sheeting system

|

Automatic stacker

|

||

|

|

M-560B |

|

Max Paper Size |

560*820mm |

|

Min Paper Size |

210*300mm |

|

Laminating Speed |

0-30m/min |

|

Paper Thickness |

105-500g/m2 |

|

Gross Power |

42/27KW |

|

Total Weight |

3900kg |

|

Overall Dimensions |

5800*1350*1600mm |

|

Pre-stacker |

1850mm |