Feeding

Convenient, adjustable regulating plates to fit manual feed

Operator replenishes sheets on the run to provide a continuous feed

Paper roll release spindle automatically unwinds paper and provides a continuous feed

Laminator

Build-in electric-heated tubes make chrome roller temperature rise fast

Precise digital temperature control

Electric hydraulic pressure system ensures big and constant laminating pressure

Film roll slitting and perforating mechanisms

Embosser

Embossing roller

Counter-pressure rubber roller

Embossing and laminating are finished in one pass

Rewinder

Spindle automatically winds the laminated sheets web

Others

Suitable for both roll-to-roll and sheet-to-sheet lamination

2 film release spindles shorten the time for film roll exchanging

User-friendly design, refined appearance, as well as compact, space-saving structure

|

Paper roll release spindle & sheets conveyor

|

Film roll slitting and perforating mechanisms

|

||

|

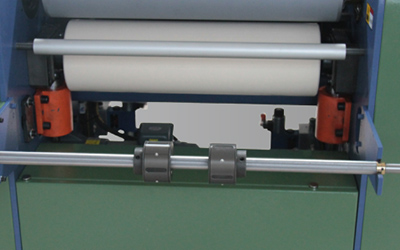

Laminating, embossing and rubber rollers

|

rewinder

|

||

|

Model |

MK-550 |

MK-780 |

|

Max Sheet Size (mm) |

550 (width) |

780 (width) |

|

Laminating Speed (m/min) |

0-30 |

0-30 |

|

Sheet Thickness (g/m2) |

100-500 |

100-500 |

|

Gross Power (KW) |

3 |

4.5 |

|

Total Weight (kg) |

400 |

450 |

|

Overall Dimensions (mm) |

1670*1200*1160 |

1670*1430*1160 |