Feeding

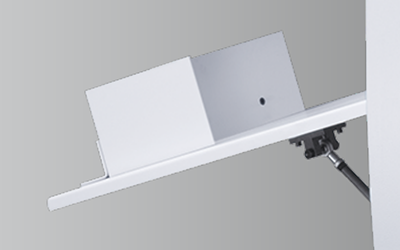

Magnetic regulating plates fit manual feed

The overlap regulator adjusts the sheets overlapped length

The operator replenishes sheets on the run to provide a continuous feed

Laminator

Electromagnetic-heated, chrome laminating roller

Counter-pressure rubber roller

Electric hydraulic pressure system provides big and constant pressure

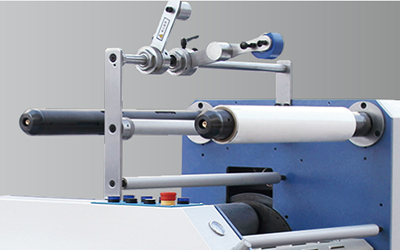

Film mounted on quick-change inflatable air-shaft

Air-shaft ensures precise film release tension and speed

Film roll slitting and perforating mechanisms

Embosser

Electromagnetic-heated, embossing roller

Counter-pressure rubber roller

Electric hydraulic pressure system provides a big and constant pressure

4 embossing rollers with different patterns are easy to exchange

Sheeter

Adjustable sheeting pressure

Stable and efficient pneumatic sheeting system

Steer wheels exert negative force on one side to help with sheeting

Sheets collecting

Height-adjustable inclined table

Others

Air-shaft II automatically winds laminated sheets web when the sheeting system is not in use

Laminating and embossing are finished in one pass

|

Overlap regulator

|

Double air-shaft

|

||

|

Electromagnetic-heated laminating unit

|

Embossing rollers with 4 patterns

|

||

|

Pneumatic sheeting system

|

Height-adjustable inclined table

|

||

|

|

SF-630-4D |

|

Max Paper Size |

630mm |

|

Laminating Speed |

0-20m/min |

|

Paper Thickness |

105-500g/m2 |

|

Gross Power |

8KW |

|

Total Weight |

1240kg |

|

Overall Dimensions |

3100*1300*1700mm |