Feeding

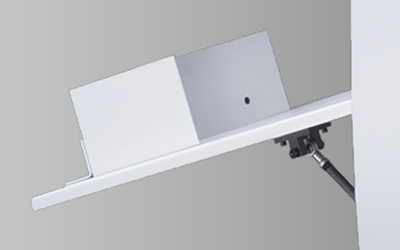

Magnetic regulating plates fit manual feed

The overlap regulator adjusts the sheets overlapped length

The operator replenishes sheets on the run to provide a continuous feed

Laminator

Electromagnetic-heated, chrome laminating roller

Counter-pressure rubber roller

Electric hydraulic pressure system provides big and constant pressure

Film mounted on quick-change inflatable air-shaft

Air-shaft ensures precise film release tension and speed

Film roll slitting and perforating mechanisms

Embosser

Electromagnetic-heated, embossing roller

Counter-pressure rubber roller

Electric hydraulic pressure system provides a big and constant pressure

Sheeter

Adjustable sheeting pressure

Stable and efficient pneumatic sheeting system

Steer wheels exert negative force on one side to help with sheeting

Sheets collecting

Height-adjustable inclined table

Others

Air-shaft II automatically winds laminated sheets web when the sheeting system is not in use

Laminating and embossing are finished in one pass

|

Overlap regulator

|

Laminating & Embosser unit

|

||

|

Pneumatic sheeter

|

Height-adjustable inclined table

|

||

|

|

SF-330 |

SF-550 |

SF-630 |

|

Max Paper Size (mm) |

330 |

550 |

630 |

|

Laminating Speed (m/min) |

0-30 |

0-30 |

0-30 |

|

Paper Thickness (g/m2 ) |

105-500 |

105-500 |

105-500 |

|

Gross Power (KW) |

15 |

15 |

15 |

|

Total Weight (kg) |

750 |

1000 |

1100 |

|

Overall Dimensions (mm) |

3000*930*1630 |

3000*1150*1630 |

3000*1230*1630 |