Feeder

Sheets pre-stacker provides a continuous feed without a stop

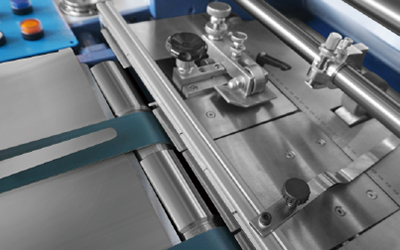

Servo-controlled feeder head (oil-free vacuum pump) replenishes sheets

Sheets gap sensor for self-protection

The overlap regulator adjusts the sheets overlapped length

Side-lay regulator aligns sheets

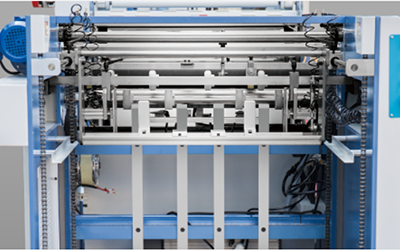

Laminator

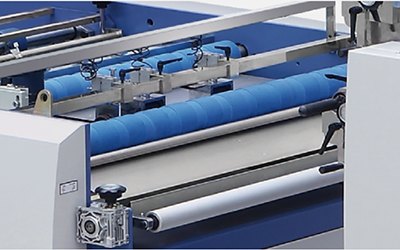

Electromagnetic-heated, chrome laminating roller

Hydraulic system provides big and constant pressure

Film mounted on a quick-change inflatable air-shaft with scales

Air-shaft ensures precise film release tension and speed

Film roll slitting and perforating mechanisms

Embosser

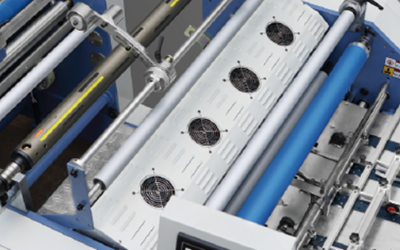

Electromagnetic-heated, embossing rollers and hydraulic pressure system

Double-sided embossing system

4 types of embossing patterns are easy to exchange

Sheeter

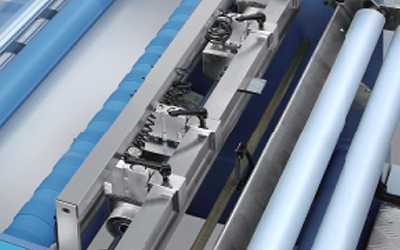

Adjustable pro-active, anti-curl bar takes the curl out of laminated sheets

Steer wheels exert a negative force on one side to help with sheeting

Adjustable sheeting pressure

Stable and efficient pneumatic sheeting system

Stacker

Non-stop stacker with the sheets counter

Others

Touch screen and control panel with colourful buttons

|

Feeder head

|

Overlap regulator

|

||

|

Side-lay regulator

|

Anti-curl assembly

|

||

|

Electromagnetic-heated laminating unit

|

Embosser with 4 patterns

|

||

|

Pneumatic sheeting system

|

Automatic stacker

|

||

|

|

M-760Y-4D |

|

Max Paper Size |

760*820mm |

|

Min Paper Size |

210*300mm |

|

Laminating Speed |

0-60m/min |

|

Paper Thickness |

100-500g/m2 |

|

Gross Power |

42 KW |

|

Total Weight |

5500kg |

|

Overall Dimensions |

6210*1650*1600mm |

|

Pre-stacker |

1850mm |